From many posts I see on the various forums, many concern the correct carburetor adjustments and settings on the CA77 305 Dream model.

Both the 250cc and 305 models use the same 22mm carburetor body with just different jets. The main settings for the common CA77 are a #35 idle jet and #120 main jet. Float level setting is 26.5mm for both models.

What seems to be occurring is that the carb kits from the Keyster company are coming in with #40 idle jets and #130 main jets, along with a poor copy of the slide needle. OEM needles will have a K#### number stamped just below the last needle clip groove.

K22402 is the needle for the 250 Dream carburetor. 16151-259-004 is the 250 needle part number

K22401 is the needle for the 305 Dream carburetor 16151-266-004 is the 305 needle part number.

The dimensions of the float valve and needle from the Keyster kits often differ from the OEM parts. The needle length and depth of the float valve seat can vary as well, causing problems with properly setting the float level.

Recently, I was trying to assist a Dream forum member who was having problems with fuel-fouling the spark plugs in just minutes. I ran the whole set of specs by him and offered other possible solutions, but the problem didn’t go away with any of his repair attempts. I happened to have what was basically an unused CA77 carburetor that came with a batch of other loose 250-305 parts. I offered it to him for sale and he eagerly made the purchase. A few days later, with both carbs in his hand, he began to compare parts and specifications. His old carb had a #40 idle jet installed, which was obviously a kit part. In comparing his old jets with the ones from the new OEM carb he determined that using some guitar strings to clean out the idle jets, the #40 in his carb would allow a .027” wire to pass through the hole.

The Keihin jets are metric-sized, so a #35 idle jet is .35mm or about .013”. So his #40 stamped idle jet was actually about a #70 size instead. Bingo! In all of his work and worry about why his bike was running so rich and kept fouling plugs, it was an over-sized pilot jet as the main culprit.

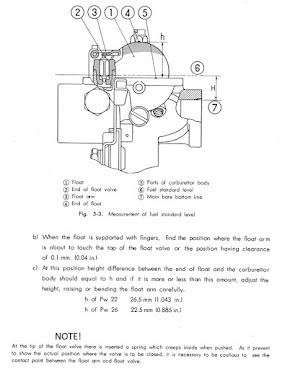

As I guided him through the carb inspection and settings process, he asked if the float valve needle was supposed to be compressed when the float level gauge was used to determine the correct height. That was incorrect! As shown in the Honda shop manual drawings and descriptions, the float height is determined by allowing the float tang to just rest on the spring-loaded tip of the float valve needle NOT compressing it. Compressing the needle will give an inaccurate float level setting and cause performance issues.

Factory Shop manual illustration

He sent photos comparing the OEM and the Keyster kit float needles and they are markedly different in size and shape. I have found that the needle seat depths are different than the OEM parts and in some cases the whole height of the float valve seat is different than the stock parts. These vital part dimensions often lead to having the floats banging up against the roof of the float chamber when the float height is set with these inaccurately sized parts.

The kit needles are often incorrectly made. My friend, Ed Moore, said that the Keyster carb needles for the CB77 kits actually work well on CL77 carb applications. When used on CB77 engines, they tend to run rich,, causing plug fouling or just poor part throttle performance. Unfortunately, there are few remaining companies that provide carb kits for 60 year old Honda motorcycles, however, the ones being produced have had the same problems for the last 20 years. I have had to use a paper punch to notch the float bowl gaskets on the square bowl carburetors because the material was stamped too wide and the gaskets flip up against the two guide posts on the front straight side of the carburetor bodies.

In cases where air filters have been changed to a different type or just left off completely, the fuel metering will be insufficient, so an increase will need to be made on the main jet. The same can be said for a change in the exhaust system where aftermarket mufflers are used in place of the OEM originals. At times, the needle clip position will have to be changed in order to smooth out the transition period from idle to mid-throttle positions. You have to test ride and make determinations about what the engine actually wants, once you have deviated from OEM intake and exhaust systems. Raising the choke slowly when the engine is struggling will be a helpful indicator to determine that the engine is running lean at part throttle.

When you are tuning up any of the 250-305 engines, knowing the stock specs and settings is crucial as a starting point for further adjustments. For Dreams, it is #35/#120 jet combo that is the starting point. Of course, erratic ignition timing and air leaks at the flange and insulators can cause upsets with the stock settings.

07/25

Bill Silver aka MrHonda

www.vintagehonda.com

Hi Bill, I ride a CL77 with the stock pipes with snuff or nots. The motor pulls well and has stock jetting with the Keihin original brass. Once I get things dialed in from idle and running up through the rpm range. It puts a smile on my face. We just need to ride them and not let them sit in our garages or outside. Adjusting the carbs just takes patience so they're not a mystery to us riders. Thanks for your post today.

ReplyDelete